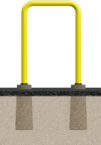

Hot-dip galvanizing is a durable, environmentally friendly, and economical option that protects steel from corrosion caused by exposure to the environment.

In addition to excellent corrosion resistance, hot-dip zinc repairs damage caused during installation or operation. Thanks to cathodic protection, zinc corrosion products fill in any points of damage. For this reason, hot-dip galvanizing is a recommended surface treatment method in the construction industry, e.g., for lighting poles.

Hot-dip zinc provides excellent and maintenance-free corrosion protection for decades.

Hot-dip galvanizing process

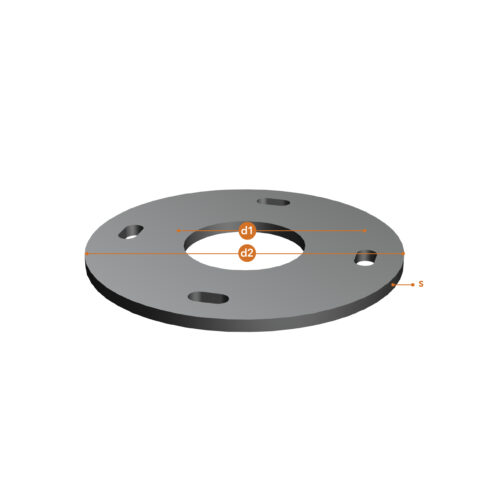

Our hot-dip galvanizing complies with the international EN ISO 1461 standard, which guarantees a functional process.

The steel is cleaned by phosphating in dilute hydrochloric acid. Rust and mill scale is removed during phosphating. After rinsing with water, the pieces are submerged in a flux bath, where a protective layer of salt enters the surface. This prevents the steel from oxidizing before the actual zinc bath.

Following the cleaning stages, the structure is immersed in molten (450°C) zinc. Zinc and pure steel react together and form a coating (3-layered phase bonding + pure zinc). We use low silicon steel in our products, which is well suited to this process.